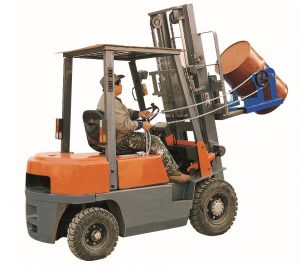

HK285A and HK285B forklift karrier is used together with the forklift as a forklift accessory, it will converts your fork truck into a drum handler. Easily lift transport, raise and tilt loaded steel drums, workers just need to control the 10" pull-chain loop to control the drum's rollover without leaving the forklift seat.

It has 30:1 ratio and a forklift pocket, so it can be easily used together with the forklift.

We have this item in stock in France, if you are located in Europe, we can arrange delivery to you ASAP! This way will save your time and shipping cost.

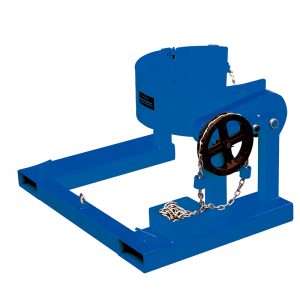

| Model | HK285A | HK285B |

| Capacity kg(lb.) | 364(800), steel drum | 680(1500), steel drum |

| Drum size | 572 mm(22.5’’)diameter, 210 liters(55 gallon) | 572 mm(22.5’’)diameter, 210 liters(55 gallon) |

| Fork opening | 24-2/5’’ (620mm) apart | 24-2/5’’ (620mm) apart |

| Fork pockets | 2-1/2’’ high *7’’ wide (65*180mm) | 2-1/2’’ high *7’’ wide (65*180mm) |

| Net weight kg(lb.) | 70(154) | 97(214) |

The Features of Forklift-Karrier:

- Converts your fork truck into a drum handler.

- HK series Fork-Carrier can easily lift, transport, raise, and tilt loaded drums.

- The 10’ pull-chain loop allows control from the driver’s seat.

- It has 30: 1 ratio.

Attention and Warning:

- Please add a little light mechanical lubricant to each moving part before use to ensure the safety and reliability of each part. Confirm that the weight of the drum and its contents is not greater than the rated load of this product.

- When using, connect the lifting ring on the four corners of the equipment to the sling, and make sure that the connection is strong enough and the lifting capacity of the sling is enough to ensure the safety of the operation. During the work, personnel should not be allowed under the bucket clamps and barrels.

- When carrying the barreled materials, the operator should first lift the clamp to the top of the bucket and align the clamp core frame with each bucket. If the position of each bucket is slightly separated, the guide spokes of the clamp can be automatically adjusted. The range allows the clip to work properly. In this way, not only can work efficiency be improved, but also the barrels can be arranged neatly and beautifully during stacking.

- When the bucket is lowered, the bucket is stabilized, and the fixture is dropped to the dead point, and then the crane is lifted, and the jaws are automatically relaxed.

- When clamping and loosening the drum, the clamp must be vertically moved to prevent movement or damage to the drum.