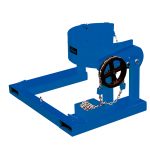

DT series hydraulic drum truck is ideal for lifting and transporting steel drums with a top lip. DT250 is used for drums on the floor and DTR250 has a straddle leg for picking up drums from a pallet (standard Euro Pallet).

Spring-loaded steel jaws securely grip the top lip of the drum to prevent oil drums from falling off. Simple design is easy to use, unit features a manual mechanical hand ratchet crank lift mechanism.

We have this item in stock in France, if you are located in Europe, we can arrange delivery to you ASAP! This way will save your time and shipping cost.

| i-Lift No. | 1710401 | 1710501 | 1710402 | |

| Model | DT250 | DTR250 | DTW250 | |

| Lifting Capacity | kg(Ib.) | 250(550) | ||

| Max.Drum Height | H1 mm(in) | 1220(48) | 1180(46.5) | 1220(48) |

| Min Drum Height | H2 mm(in) | 900(35.4) | 900(35.4) | 900(35.4) |

| Drum Size | mm(in.) | 572,210 Lifters(55gallon) | ||

| Net Weight | kg(Ib.) | 42(93) | 50(110) | 45(93) |

Video

Attention and warning:

- The operator must read and fully understand the specification before using it.

- Do not use the drum truck if it needs to be repaired.

- Do not exceed the rated load of the drum truck.

- When no lifting is required, the oil drum should be placed in a lower position.

- When carrying the oil drum, the oil drum can be removed from the ground without having to raise the oil cylinder too high.

Installation:

- Open the packaging carton, take out the fork assembly (2), the cylinder assembly (3), the connecting screw (4), the operator

Handle (5), connecting bolt (11), cylinder base (12), confirm that the parts are complete.

- Fix the fork assembly (2) and the cylinder base (12) with the connecting bolts (11).

- Place the cylinder assembly (3) on the cylinder base (12) and secure with the connecting screw (4).

Insert the operating handle (5) into the pump seat on the cylinder assembly (3) and secure with screws.

Operating:

- Raise the oil drum

Move the hydraulic oil drum truck to the front of the oil drum, and make the front end of the lower support plate of the locking block (8) close to the oil drum, and press the rear wheel (1) to brake. When the operating handle is pulled, the locking block (8) rotates downward to clamp the oil drum, and the bumper (7) rotates downward, and continues to move the operating handle, and the oil drum rises.

- Carrying oil drums

After the oil drum is raised, release the brake and push or pull the operating handle to carry the oil cylinder. (It is not necessary to raise the oil cylinder too high)

- Put down the oil drum

After transporting the oil drum to the desired location, pull the bumper (7), slowly release the lowering valve stem (6), the oil drum descends to the ground, the locking block (8) releases the oil drum, and pulls the bumper (7), tighten the lowering valve stem (6).

Note: When lowering the oil drum, do not loosen the valve stem too fast.