Introduction of Work Positioner

The Electric Work Positioner is a compact and versatile lifting solution designed to make material handling safer, faster, and more ergonomic. Powered by an efficient electric motor, it allows precise lifting and lowering of goods with minimal physical effort, reducing the risk of workplace injuries.

Ideal for warehouses, production lines, laboratories, and retail environments, the electric work positioner can easily handle boxes, components, tools, and other materials. Its lightweight design, smooth mobility, and adjustable lifting platform make it perfect for tight spaces and frequent use.

Whether you need to lift, transport, or position loads at an optimal working height, this electric work positioner offers excellent performance, reliability, and user comfort — improving efficiency and productivity across your operation.

Features of Work Positioner

- All these optional standard accessories are available in various special versions.

- E type is also available in an AISI 304 stainless steel version for use in sterilised areas or food sectors.

- Powerful motor, battery 12Ah &20Ah. A range of highly maneuverable, lightweight lifts, designed to take the strain out of any lifting job ground level to over shoulder height.

- Ideal for use in narrow aisles and confined spaces. Perfect for all applications from pharmaceutical to catering, from packing line to food processing, from warehouse to office, kitchens, laboratories, retail outlets and son on.

- Weighing system is also opptional.

- E series automatic electronic overload protection system ensures safety. maintance free and sealed batteries, automatic charger.

The Electric work positioner lift truck has models E100R, E150R, E180N, E250N, E300N, and the work positioner is also with weight scales like model E100W, E150W, E180W, E250W, E300W.

Details of Work Positioner

Video show:

We have this item in stock in France/US, if you are located in Europe or US, we can arrange delivery to you ASAP! This way will save your time and shipping cost.

| i-lift No. | 1551507 | 1551508 | 1551509 | 1551510 | 1551505 | 1551506 | 1551511 | |

| Model | M100R | M200R | E100R | E150R | E180N-1/E180N-2 | E250N | E300N | |

| Type | Manual | Electric | ||||||

| Capacity | kg(lb.) | 100(220) | 200(440) | 100(220) | 150(330) | 180(396) | 250(550) | 300(660) |

| Max.ForkHeight | mm(in.) | 1500(60) | 1700(67) | 1500(60) | 1600(63)/1900 (75) | 1900(75) | 1900(75) | |

| Min.ForkHeight | mm(in.) | 130(5.1) | ||||||

| Platform Size | mm(in.) | 470x600(18.5x23.6) | 480x610(18.9x24) | 470x600(18.5x23.6) | ||||

| Overall Size | mm(in.) | 840x600x1830 (33.1x23.6x72) | 870x600x1920 (34.3x23.6x75.5) | 870x600x1990 (34.3x23.6x78.3) | 870x600x1790 (34.3x23.6x70.5) | 870x740x1920(2220) (33.5x29.1x75.5(86.6)) | ||

| Battery | mm(in.) | 24V/12Ah | 24V20Ah | |||||

| Net Weight | kg(lb.) | 50(110) | 60(132) | 66(145.2) | 63(138.6) | 85(187) | 90(198) | 105(231) |

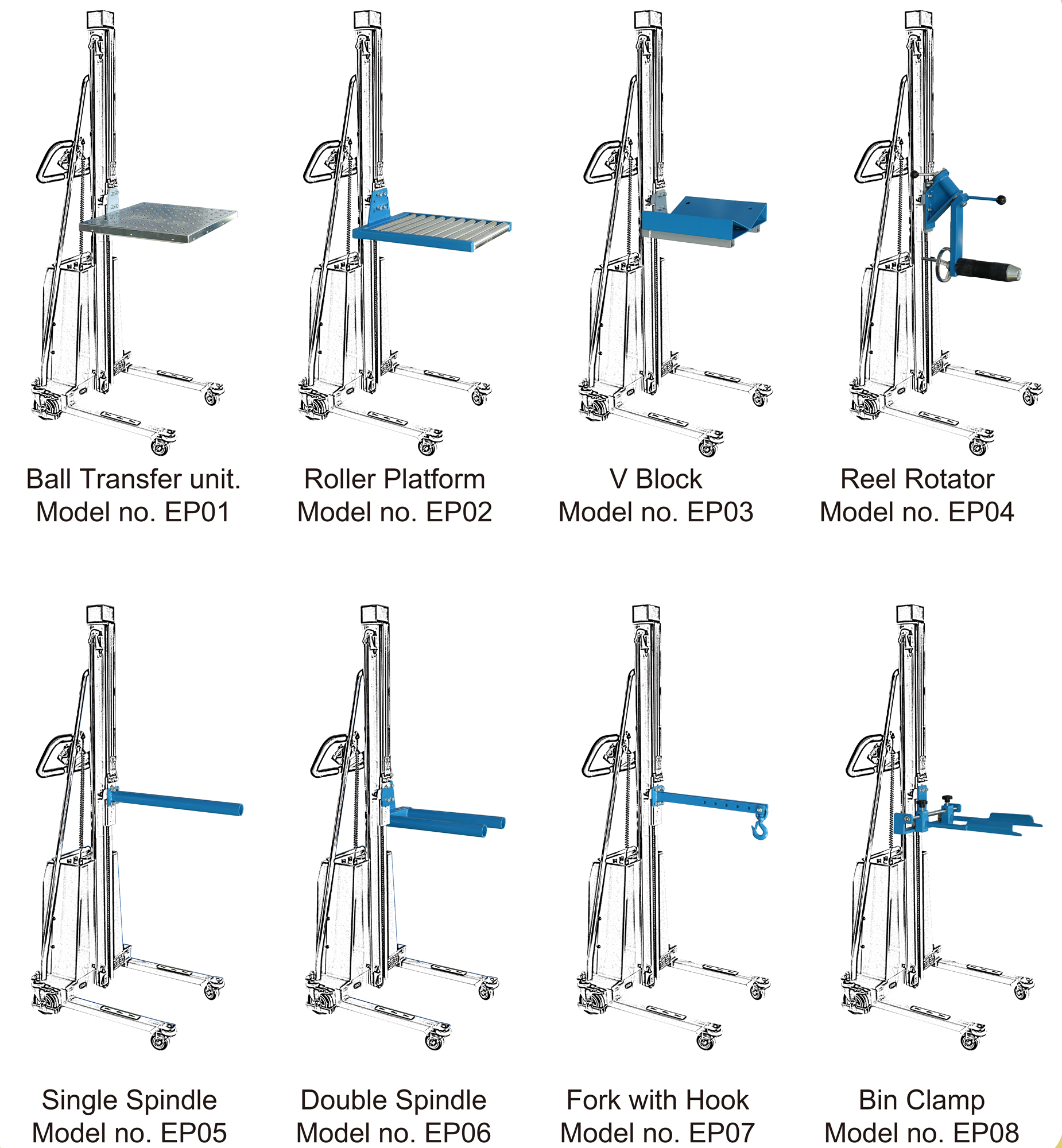

Quick change attachments available: The platform can be changed to Ball transfer unit, roller platform, V block or spindle, Fork with Hook and even Clamp.

As a work positioner manufacture, i-Lift also provide electric stacker, weighing work positioner manual work positioner platform work positioner, manual hydraulic stacker, light stacker, high lift electric stacker and so on.

Operation Guide of Electric Work Positioner

1) Elevator: Operation of Transition, Loading and Unloading.

1.1 Lock truckles before goods loading and unloading at any height.

1.2 Take care of load uniformity when load and unload; deflected load is always not appreciated.

1.3 Mention not to loose equilibrium from one-sided unloading lest dangerous occurrences.

1.4 When it is needed to move the elevator with unfinished unloading, take care of the uniformity of the gods still needed to be unloaded.

1.5 Lower the platform of the electric work positioner to the lowest position when the loaded elevator is to move, sa as to ensure safety.

2) Elevator: Operation of Climbing and Descending

2.1 Take care to stop at a right spot and ensure needed operation space when the elevator is to pile or take off goods for some height.

2.2 Lock the wheels, and switch power on.

2.3 Press on the UP button on the panel, the platform climbs smoothly to the needed height, and then release the button, the platform keeps still and shall no slip down. The movable hand control panel is convenient for the operator to observe and operate on different positions.

2.4 Strictly follow the regulations to operate the elevator when goods raised up to the needed height for unloading or piling.

2.5 Strictly follow the regulations to operate the elevator when taking off goods from racket.

2.6 When finishing unloading at some height, press the SOWN button for the platform descending smoothly; and the DOWN button can be released at any height needed while the platform shall stop descending for the elevator to perform a new job at same spot but different height.

2.7 The elevator is designed to possess the function of overload protection. Whenever the load surpassed 25% of rated capacity, the platform shall not be elevated, the elevator shall not be able to carry out the jobs of up-climbing, down-descending and vehicle transition.

2.8 The electric work positioner elevator is designed to possess the function of low power protection. Should the cell power is not sufficient for jobs during loaded climbing and descending, the buzzer beeps for 50 seconds alarm continuously and then cut off automatically the power circuit with indication light up (operator shall lower the platform to the lowest position during this period); the elevator is protected and the operation of climbing or descending is invalid even if the power is still connected.

3) Cell

3.1 High performance petty maintenance-free sealed acidic-lead storage cell is selected to power the elevator. It is characterized by low discharge ability, safe, easy mounting and change=over, and can be used under the ambient temperature range o f -15ºC~50ºC.

3.2 The working life of the cell is greatly depends on the right use. The working life of the cell shall be greatly shortened when repeatedly used at the condition of low voltage, and even burn the control element. Considering of this, the elevator is designed with the function of low voltage protection in the part of electric control. During the elevator is operating under low voltage for up-climbing or down-descending, the buzzer shall beep for 50 seconds continuously and then cut off the power supply. The operator shall charge the cell in time.

4) Charger

4.1 High performance charger is provided together with the elevator, so that the cell can be chares at any handy power terminal. Be sure the voltage of local power net is as needed by the inlet voltage of the charger.

4.2 When charging with switch off elevator power, connect charger source pin and power terminal socket, the red indicator of source power of the charger is lit up, while the charging status green indicator is lit, that means the cell is tin the status of charging; and when the green indicator faded, that means the cell is charged full. Generally, the charging period takes 10~12 hours.

4.3 Shall the charged cell show low voltage status during heavy duty job, probably the cell is damaged or the charger is in trouble. Warning Use only on plain and smooth floor. Don’t overload, ensure load uniformity. Pay special attention when heavily loaded. Buzzer beeps to alarm cell low, charge in time or the cell shall be damaged. Ensure that the input voltage of the charger complies with local power net voltage.

This series of Electric Elevators are easy to handle with, safe and reliable, automatic and labor saving by small but high efficient and maintenance free cell power supplying, reliable small motorized chain driving , high performance panel control; movable electric push buttons control the movements of platform or other accessory upward or downward. This series of Work Positioner are mainly used for goods transition, elevation or piling, or taking off and transiting goods at some certain height on plain and smooth floor. The characteristics of pretty appearance, high intensity aluminum alloy pole, convenient and movable electric control, automatic and labor saving make the elevators be extensively used in. Especially, the configuration of several accessories and provision grade platform make the elevators be specially applied in transition of small column shaped working pieces, such as in packing material printing factories, super-markets, hotels and etc.