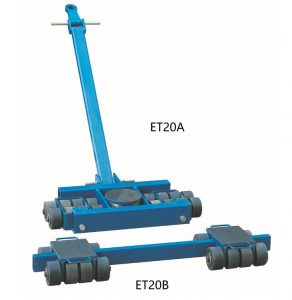

ET series steerable skates are professional class. You can get smooth running on the i-Lift ET series skates. Skates are available in two versions type A and B, Type A can be steerable, type B can be laterally adjustable and they can be used together or separately. Powder coated give a high quality durable finish for long-time using.

The steerable skates has different models ET3A, ET6A, ET9A, ET12A, ET20A, and can combined use with ET3B, ET6B, ET9B, ET12B, ET20B according to your working condition. If combined use the steerable state, the capacity is 6tn, 12tn, 18tn, 24tn, 40tn for heavy loading.

We have this item in stock in France/US, if you are located in Europe or US, we can arrange delivery to you ASAP! This way will save your time and shipping cost.

| i-lift No. | 1911301 | 1911302 | 1911303 | 1911304 | |

| Model | ET3A | ET6A | ET9A | ET12A | |

| Capacity | kg(lb.) | 3000(6600) | 6000(13200) | 9000(19800) | 12000(26400) |

| Loading height | mm(in.) | 110(4.4) | |||

| Roller size | mm(in.) | 85*68(3*2.7) | |||

| Number of roller | pcs | 4 | 8 | 12 | 16 |

| Dia of 180o rotating platform | mm(in.) | 170(7) | |||

| Dimensions(L*W) | mm(in.) | 270*230(10.6*9.1) | 610*520(24*20.5) | 815*600(32.1*23.6) | 990*600(39*23.6) |

| Length of Handlebar (with pulling eye) | mm(in.) | 960(37.8) | 1080(42.5) | ||

| Net weight | kg(lb.) | 15(33) | 45(99) | 56(123.2) | 73(160) |

| i-lift No. | 1911401 | 1911402 | 1911403 | 1911404 | |

| Model | ET3B | ET6B | ET9B | ET12B | |

| Capacity | kg(lb.) | 3000(6600) | 6000(13200) | 9000(19800) | 12000(26400) |

| Loading height | mm(in.) | 110(4.4) | |||

| Roller size | mm(in.) | 85*85(3*3) | |||

| Number of roller | pcs | 4 | 8 | 12 | 16 |

| Dimensions of load bearing area | mm(in.) | 150*150(6*6) | 200*220(8*8.8) | 180*170(7.1*6.7) | 200*220(8*8.8) |

| Range of connecting rod adjustable | mm(in.) | 960(37.8) | 1080(42.5) | ||

| Net weight | kg(lb.) | 16(35.2) | 32(70.4) | 34(74.8) | 45(99) |

OPERATING INSTRUCTIONS

1) Each roller must be inspected before initial use. The chain and chain rolls should move freely and the entire roller and roller parts should be 100% functional before use. The rollers should be inspected every six months after initial use.

2) When installing your roller under your heavy object, select an area that is easily accessible, and also provides the best load distribution, such as the corners of the object being moved. The point of placement should be able to support that part of the load. Lifting the object may be accomplished by a hydraulic jack, hoist, fork truck, pry bar, or any similar device depending upon the load weight. Lifting height is determined by the height of the roller. Note that the roller’s low height makes lifting or raising of the equipment minimal.

3) Particular care should be taken when installing rollers. Such care should include lifting,prying and/or jacking the loads. All relevant manufacturer’s bulletins on the use of any accessory equipment should be read thoroughly before proceeding.

4) Particular care should be paid to exact alignment of the rollers. Failure to do so could increase surface friction and, in cases of severe misalignment, cause possible shifting of the object on the roller. Rollers should be installed parallel to each other and at the same height.

5) Maximum speed of rolling surface should not exceed 10ft/min (3 meters/min).

6) If the object being moved has limited contact area or for any reason can shift, the roller should be affixed to the load in at least some temporary manner. This method of affixing the roller to the load should be able to withstand any horizontal force that might result from the load shift.

7) Particular care should be taken when moving top heavy equipment or equipment where there is a high center of gravity. The user should take all necessary precautions so that the load center is not allowed to shift even in the slightest amount. These precautions may include:

7.1 Constant monitoring of rollers.

7.2 Absolute cleanliness of moving surfaces.

7.3 Use of a temporary method of attaching roller to load.

7.4 Not moving on uneven surfaces or changing levels.

7.5 Use of preload pads.

7.6 Not turning load while moving.

7.7 Moving slowly at all times.

8) The path upon which the roller transports the heavy load should be clean of all debris and should not have sharp protrusions of any sort.

9) Check to be sure that the floor surface or subsurface cannot deflect or “sag” due to the load concentration at that point. If so, the surface must be improved.

10) Rollers should be periodically inspected in accordance with Maintenance Instructions.

11) When using Rollers, it is assumed that the user has experience in moving or transporting heavy loads and can apply the common sense practices that apply in the wise and careful methods required to move, shift or transport heavy equipment.